Picture this: You invest $2,500 in a premium mobility scooter, expecting years of reliable service, only to find yourself stranded with a dead battery after 18 months or facing a $800 motor replacement bill. According to recent industry data from 2024, 68% of mobility scooter breakdowns could have been prevented with proper maintenance protocols. Yet most owners receive minimal guidance beyond a basic user manual.

The harsh reality is that mobility scooters are complex machines with electrical systems, mechanical components, and wear parts that require systematic care. Without proper maintenance, even top-tier models can fail prematurely, leaving users without essential mobility support when they need it most.

This comprehensive guide reveals the maintenance strategies that extend scooter lifespan by 40-60% while reducing repair costs by up to 75%. You’ll discover battery optimization techniques that double performance life, tire replacement schedules that prevent dangerous blowouts, motor servicing protocols that maintain peak efficiency, and professional service networks across the USA and Canada that provide expert care when you need it.

This Photo was taken by Harry Tucker.

The hidden cost of neglected maintenance

Most mobility scooter owners treat their devices like appliances – expecting them to work reliably without regular attention. This approach costs thousands in premature replacements and emergency repairs. Industry studies from 2025 show that the average mobility scooter experiences its first major breakdown within 24 months when maintenance is neglected, compared to 5-7 years with proper care.

The financial impact extends beyond repair costs. When your scooter fails unexpectedly, you face transportation challenges, potential safety risks, and the stress of finding immediate solutions. Emergency service calls typically cost 200-300% more than scheduled maintenance visits.

Understanding your scooter as a sophisticated mobility system with interdependent components changes everything. Like a vehicle, it requires systematic attention to batteries, motors, tires, electrical systems, and mechanical parts. This proactive approach transforms maintenance from a burden into an investment in independence and reliability.

Battery care optimization: maximizing power and lifespan

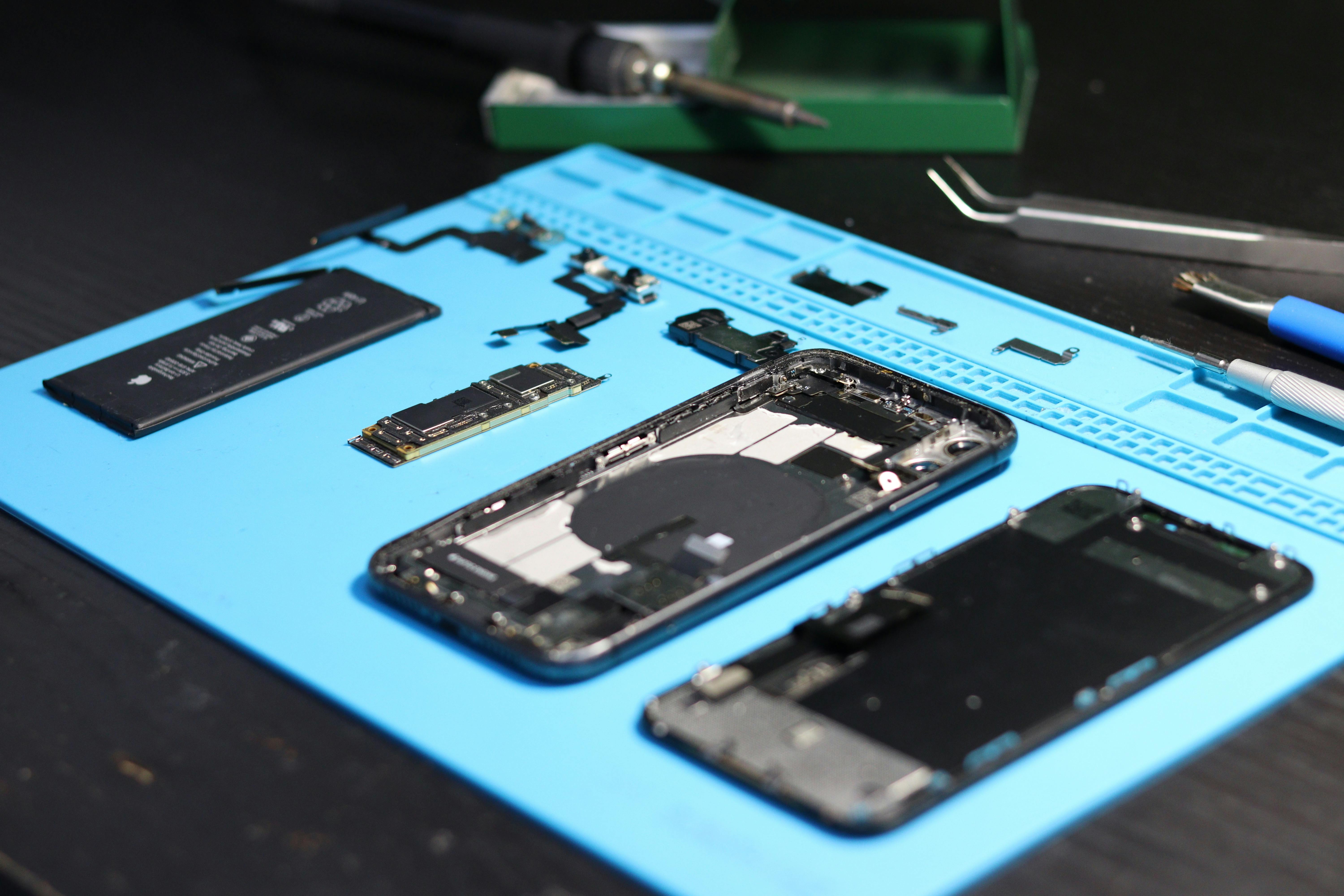

Your mobility scooter’s battery system represents 30-40% of its total value and directly impacts performance, range, and reliability. Modern lithium-ion and AGM batteries can deliver 3-5 years of excellent service with proper care, but deteriorate rapidly under poor maintenance practices.

Understanding battery chemistry and behavior

Most mobility scooters use either lithium-ion or sealed lead-acid (AGM) batteries, each with specific care requirements. Lithium batteries offer superior energy density and longer lifespans but require precise charging protocols. AGM batteries are more forgiving but heavier and less efficient.

Temperature significantly affects battery performance and longevity. Operating batteries below 32°F (0°C) or above 85°F (29°C) reduces capacity and accelerates degradation. For users in extreme climates, understanding regional climate adaptation strategies becomes essential for optimal battery performance.

This Photo was taken by Max.

Charging best practices for maximum longevity

Proper charging habits can double battery lifespan. Always use the manufacturer-specified charger, as voltage and amperage mismatches cause irreversible damage. Charge batteries after each use, even for short trips, as partial discharge cycles are less stressful than deep discharges.

Avoid overcharging by unplugging the charger once the battery reaches full capacity. Most modern chargers include automatic shut-off features, but older units may continue supplying current, causing electrolyte loss and plate damage in AGM batteries.

Store batteries at 50-80% charge when not in use for extended periods. Monthly maintenance charges prevent sulfation in lead-acid batteries and voltage depression in lithium systems. For seasonal storage, consider professional battery conditioning services.

Ultra Lightweight 27.5 lbs Carbon Fiber Folding Electric Scooter

Rating: ⭐⭐⭐⭐⭐ 4.6 | Price: $1,699.00

Airlines-approved ultra-lightweight design with premium carbon fiber construction. Perfect for travel with included basket and charger. Cons: Higher price point, limited weight capacity compared to heavier models.

Battery monitoring and diagnostic techniques

Regular battery testing prevents unexpected failures. Use a digital multimeter to check voltage levels monthly. Fully charged 12V batteries should read 12.6-12.8V, while 24V systems should show 25.2-25.6V. Voltages below these ranges indicate capacity loss or charging issues.

Monitor charging times as an early warning system. Batteries that take significantly longer to charge or reach full capacity quickly may have internal damage. Professional load testing annually provides detailed capacity assessments and remaining lifespan estimates.

Document battery performance in a maintenance log. Track charging times, voltage readings, and range observations. This data helps identify gradual degradation and supports warranty claims when necessary.

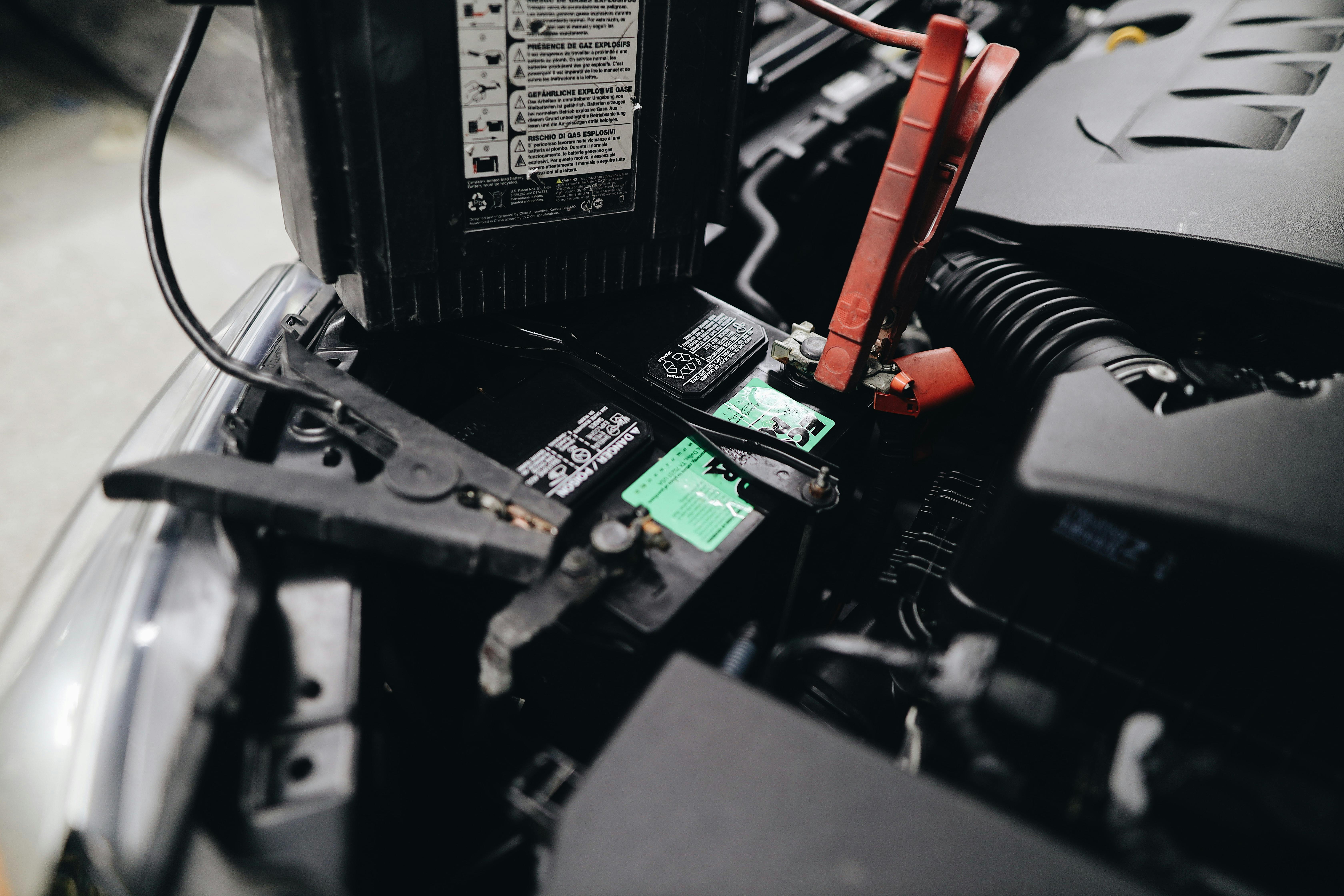

Tire replacement schedules and safety protocols

Mobility scooter tires endure unique stresses from frequent starts, stops, and tight turning radii. Unlike automotive tires, scooter tires often show wear patterns related to user habits, terrain, and load distribution rather than simple mileage accumulation.

Tire wear patterns and replacement indicators

Inspect tires monthly for uneven wear, cracks, bulges, or embedded objects. Front tire wear typically occurs on the center tread from steering forces, while rear tires may show edge wear from acceleration and braking. Pneumatic tires require pressure checks weekly, as underinflation accelerates sidewall damage and reduces efficiency.

Replace tires when tread depth reaches 2mm or when sidewall cracking appears. Don’t wait for complete tread loss, as reduced traction compromises safety, especially on wet surfaces or inclines. Consider replacing tires in pairs to maintain balanced handling characteristics.

This Photo was taken by Towfiqu barbhuiya.

Tire selection for different conditions and usage patterns

Choose tire types based on your primary operating environment. Pneumatic tires provide superior comfort and traction but require regular pressure maintenance and puncture repairs. Solid rubber tires eliminate puncture risks but offer less shock absorption and may cause vibration on rough surfaces.

For winter conditions, specialized tires with enhanced tread patterns improve traction on snow and ice. Users in harsh climates should review winter weather performance guides for comprehensive cold-climate tire recommendations.

| Tire Type | Lifespan (Miles) | Terrain Suitability | Maintenance Level |

|---|---|---|---|

| Pneumatic | 1,500-2,500 | All surfaces, excellent comfort | High (pressure, punctures) |

| Solid Rubber | 3,000-4,000 | Smooth surfaces, durability | Low (visual inspection only) |

| Foam-Filled | 2,000-3,000 | Mixed terrain, puncture-proof | Medium (visual inspection) |

MS08 4-Wheel Mobility Scooter – 15 Miles Range

Rating: ⭐⭐⭐⭐⭐ 4.8 | Price: $399.99

Compact and portable with rotating seat and 350W motor. FSA/HSA eligible with excellent value proposition. Cons: Limited to 300lbs capacity, shorter range than premium models.

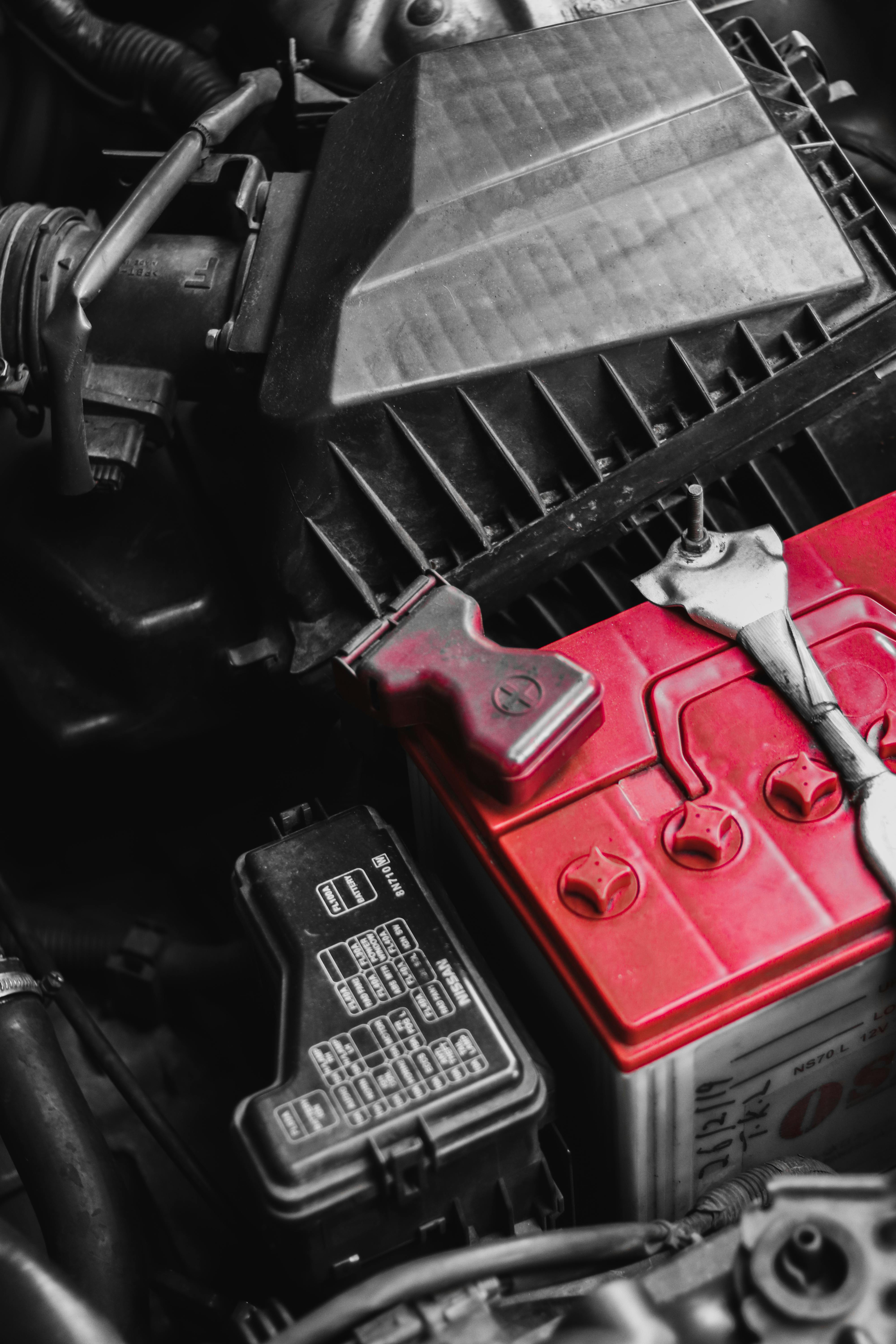

Motor servicing and performance optimization

Electric motors in mobility scooters operate under constant load variations, from smooth acceleration to steep incline climbing. These demands create wear patterns that require specific maintenance approaches to preserve efficiency and prevent premature failure.

Brushed vs brushless motor maintenance

Brushed motors require carbon brush replacement every 12-18 months depending on usage intensity. Symptoms of worn brushes include reduced power, sparking visible through ventilation slots, and unusual noise during operation. Brush replacement is typically a 30-minute procedure for qualified technicians but requires specific tools and expertise.

Brushless motors eliminate brush maintenance but require more sophisticated electronic speed controllers. These systems benefit from periodic electrical connection cleaning and thermal management. Keep motor housings free from debris accumulation that can block cooling airflow.

This Photo was taken by Vlad.

Lubrication and cooling system maintenance

Motor bearings require annual lubrication with manufacturer-specified grease. Over-lubrication attracts dirt and debris, while insufficient lubrication causes bearing wear and noise. Professional service includes bearing inspection and replacement when play or roughness develops.

Cooling systems prevent motor overheating during extended use or challenging terrain. Clean cooling fins monthly with compressed air, removing accumulated dust, leaves, and debris. Blocked cooling reduces motor efficiency and can trigger thermal protection shutdowns.

Monitor motor temperature during normal operation. Motors that become excessively hot during typical use may have internal issues, inadequate cooling, or controller problems requiring professional diagnosis.

Preventive maintenance checklists for peak performance

Systematic maintenance prevents small issues from becoming expensive failures. These checklists organize tasks by frequency, ensuring all critical systems receive appropriate attention without overwhelming daily routines.

Daily and weekly maintenance routines

Daily inspection checklist:

- Check battery charge level and charging indicator function

- Inspect tires for proper inflation and visible damage

- Test all control functions: throttle, brake, lights, horn

- Verify seat, armrests, and backrest security

- Clean any debris from motor cooling vents

Weekly maintenance tasks:

- Measure tire pressure and inflate as needed

- Clean battery terminals and check connections

- Inspect electrical connections for corrosion or looseness

- Lubricate seat adjustment mechanisms

- Document any unusual noises, vibrations, or performance changes

This Photo was taken by Vlad.

Monthly and seasonal maintenance protocols

Monthly maintenance addresses components that change gradually over time. Test battery voltage under load, inspect brake function and adjustment, and examine structural components for cracks or wear. Clean and protect exposed metal surfaces from corrosion, especially in coastal or winter salt environments.

Seasonal maintenance prepares your scooter for changing weather conditions. Spring preparation includes comprehensive cleaning, electrical system testing, and tire replacement if needed. Fall maintenance focuses on battery conditioning, weatherproofing checks, and storage preparation.

For users who travel with their scooters, understanding airport and air travel requirements ensures proper preparation and documentation for maintenance-related components.

Heavy Duty Mobility Scooter with Roof & Windshield

Rating: ⭐⭐⭐⭐⭐ 5.0 | Price: $2,896.00

Premium heavy-duty design with weather protection, 500lbs capacity, and 800W motor. Includes remote keys and long-range battery. Cons: High price point, requires significant storage space.

Professional service networks and certification standards

While many maintenance tasks are user-friendly, complex electrical diagnostics, motor rebuilds, and warranty repairs require professional expertise. Selecting qualified service providers ensures proper repair techniques and maintains warranty coverage.

Certified service provider identification

Look for technicians certified by major mobility equipment manufacturers or organizations like the National Registry of Rehabilitation Technology Suppliers (NRRTS). These certifications indicate training in proper diagnostic techniques, safety protocols, and warranty procedures.

Authorized dealers provide manufacturer-trained service and genuine replacement parts. Independent shops may offer competitive pricing but verify their experience with your specific scooter model and access to technical documentation.

This Photo was taken by Julia Avamotive.

Service networks across USA and Canada

Major mobility equipment chains like Scooter Direct and SpinLife maintain service networks across North America. These networks provide standardized service quality and parts availability, particularly valuable for travelers or seasonal residents.

Regional service providers often develop expertise in local conditions. Coastal technicians understand salt corrosion issues, while mountain region specialists know altitude and temperature effects on performance. For workplace users, consulting workplace integration guides helps coordinate professional service with accommodation requirements.

Mobile service options bring technicians to your location for routine maintenance or repairs. This convenience factor particularly benefits users with limited transportation alternatives or those managing multiple scooters in facility settings.

Warranty considerations and documentation

Maintain detailed service records for warranty claims and resale value. Document all maintenance activities, including dates, mileage, and parts replaced. Photograph any damage or wear patterns that develop over time.

Understand warranty coverage limitations regarding maintenance requirements. Many warranties void coverage if recommended service intervals are missed or if unauthorized repairs are attempted. Professional service documentation proves compliance with warranty terms.

S1 Powered Mobility Scooter – 25 Miles Range

Rating: ⭐⭐⭐⭐⭐ 4.5 | Price: $729.99

All-terrain folding design with impressive 25-mile range and height adjustable seat. HSA/FSA eligible with excellent value. Cons: Heavier than ultra-portable models, longer charging time.

Cost analysis and financial planning

Understanding maintenance costs helps budget for reliable mobility and evaluate the true cost of ownership. Data from 2024 indicates that proper maintenance reduces total ownership costs by 35-50% over a typical 5-year lifespan while improving resale values significantly.

Annual maintenance budget planning

Budget 8-12% of your scooter’s purchase price annually for maintenance and repairs. A $3,000 scooter should receive $240-360 in annual maintenance investment. This covers routine service, wear parts replacement, and minor repairs while building reserves for major component replacement.

Preventive maintenance costs significantly less than emergency repairs. Annual professional service typically costs $150-250 but prevents failures that can cost $500-1,500 to repair. Battery replacement every 3-4 years represents the largest maintenance expense at $200-600 depending on type and capacity.

This Photo was taken by Bulat369 🌙.

Financing options and assistance programs

Many service providers offer maintenance plans that spread costs over monthly payments. These plans often include priority scheduling, discounted parts, and emergency service coverage. For users exploring funding options, reviewing financing and payment strategies reveals additional resources for maintenance budgeting.

Some insurance plans and government assistance programs cover maintenance costs for medically necessary mobility equipment. Veterans’ benefits, state disability programs, and private insurance may reimburse professional service costs when properly documented and prescribed.

| Maintenance Category | Annual Cost Range | Professional vs DIY | Frequency |

|---|---|---|---|

| Routine Service | $150-250 | Professional recommended | Annual |

| Battery Replacement | $50-150 (annual reserve) | DIY possible | 3-4 years |

| Tire Replacement | $40-120 | DIY with tools | 1-2 years |

| Brake Service | $30-80 | Professional preferred | 2-3 years |

Smart technology integration and maintenance monitoring

Modern mobility scooters increasingly feature connected technologies that enhance maintenance monitoring and diagnostic capabilities. These systems provide real-time performance data, predictive maintenance alerts, and remote monitoring options that transform traditional maintenance approaches.

Diagnostic systems and performance monitoring

Advanced scooters include onboard computers that track battery cycles, motor temperature, usage patterns, and component performance. This data identifies maintenance needs before failures occur and optimizes service scheduling based on actual conditions rather than arbitrary time intervals.

Smartphone apps connected to scooter systems provide maintenance reminders, performance trends, and diagnostic trouble codes. For tech-savvy users, exploring smart technology integration options reveals additional monitoring and maintenance capabilities.

This Photo was taken by JS Leng.

Predictive maintenance and alert systems

Machine learning algorithms analyze usage patterns and component wear to predict maintenance needs. These systems send alerts when battery performance declines, tire pressure drops, or motor efficiency decreases beyond acceptable thresholds.

Cloud-based monitoring services aggregate data from multiple scooters to identify common failure patterns and optimize maintenance schedules. Fleet managers and healthcare facilities particularly benefit from centralized monitoring that coordinates service across multiple units.